Igknighters Compete at Ra Cha Cha Ruckus

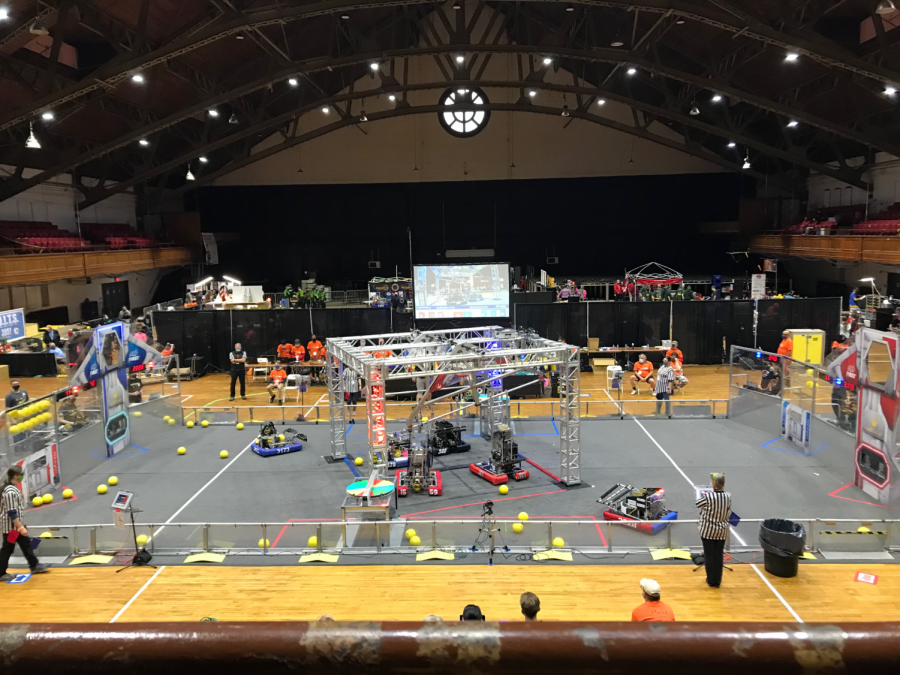

The McQuaid robotics team, the IgKnighters, competed in the Ra Cha Cha Ruckus tournament at the Rochester Armory on October 30. Despite some unforeseen technical challenges, the Team performed well, even securing an alliance that enabled them to challenge the competition’s second-place finisher.

Team members include driver Bryan Lanahan ’22, operator Ethan Danielak ’23, human player Carlo McNally ’23, technician Brennen Puth, and coach Matteo Tifone ’23.

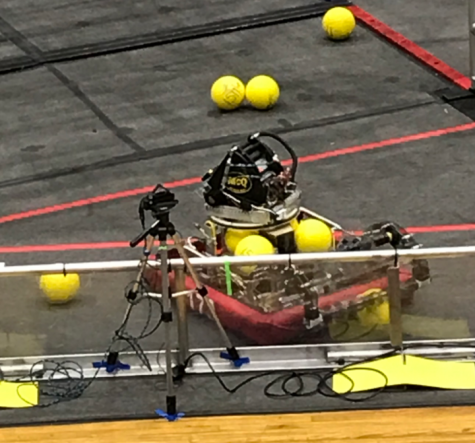

After a few months of designing and building the robot, the IgKnighters were ready to compete. The robot, Spitfire, was designed to pick up and propel a dodge ball and was controlled by two team members: one driver, and one operator.

In the competition, there were six robots on the field, broken down into two teams of three. The goal of each trio was to pick up balls and throw them at a target on top of a tower, which they would gain three points if completed, while also preventing other teams from scoring.

The judges were also looking for penalties. if one robot touches another in the safe zone, the team whose robot was touched would be given 15 points.

Though some issues came up, the IgKnighters performed quite well. Drive team member, Bryan Lanahan ‘22 said, “We performed quite well with what we had, but the shooter had some issues. When we were practicing before it worked fine, but for some reason it did not work on the field. So we resorted to defense and blocked other robots from scoring, and we did quite well.”

Though technical problems occured, the IgKnighters adapted quickly to their situation and helped the other robot on their team score along with stopping other robots.

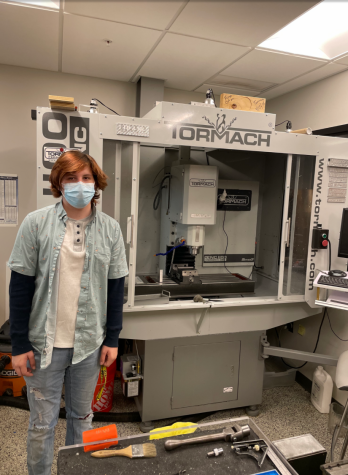

The Igknighters have acquired some interesting equipment to help with building and designing, such as their CNC Mill.

CNS stands for “Computer Numerical Control,” and it helps the IgKnighters build parts for their robots.

Mentor Luca Tifone ‘14 said, “What the CNC essentially does is it allows you to take a 3D model that you have drawn, and allows you to make that into a real object. You start with a model, then you tell the computer what tools you want to use and how you want to use them. The computer then makes coordinates that you give to the CNC Mill. Then the CNC Mill spins up to the speed you want it to go at, and then hopefully makes the right part at the end of the day.”

CNC Mills are not to be confused with a 3D printer which is additive, meaning it makes a 3D model by adding material in layers, while CNC Mills cut away at a piece of material already there.

Many members of the IgKnighters are excited and happy to have a CNC Mill because it makes the process of building robots easier and more efficient.

“I’m really happy the team has it because it has the capability of making parts that we would not be able to make by hand or with a different machine, it also is a good learning experience working with this kind of equipment,” IgKnighter Anthony Viola ‘24 said,

Kosten came to McQuaid Jesuit in 6th grade in 2016. He is one of the leaders of the Pride Alliance and Modern History Club. He enjoys participating in...